In fields like architecture, transportation, and industrial design, stainless steel is a highly favored material due to its excellent corrosion resistance, strength, and aesthetic appeal. However, when it comes to making a choice, should you use traditional solid stainless steel or the more modern stainless steel composite panel? These two materials each have their own pros and cons, and understanding their differences is crucial for making an informed decision.

Solid stainless steel refers to a sheet made from a single, homogeneous stainless steel material. Its advantages are clear:

Exceptional Strength and Durability: The uniform and dense structure of solid stainless steel allows it to withstand high mechanical stress and provides excellent resistance to impact and abrasion.

Outstanding Corrosion Resistance: The entire sheet possesses the corrosion-resistant properties of stainless steel. Even if the surface is damaged, the underlying material continues to resist rust, making it ideal for use in harsh environments.

Easy to Fabricate and Weld: The fabrication process for solid stainless steel is mature, allowing for various complex forming, cutting, and welding techniques to meet diverse design needs.

However, the drawbacks of solid stainless steel are just as apparent. First is its weight. Solid stainless steel has a high density, which results in a heavy material per unit area. This can be a challenge in fields like architecture and transportation where structural load is a significant consideration. Second is the cost. Because it requires a large amount of raw stainless steel, the price of solid stainless steel is relatively high.

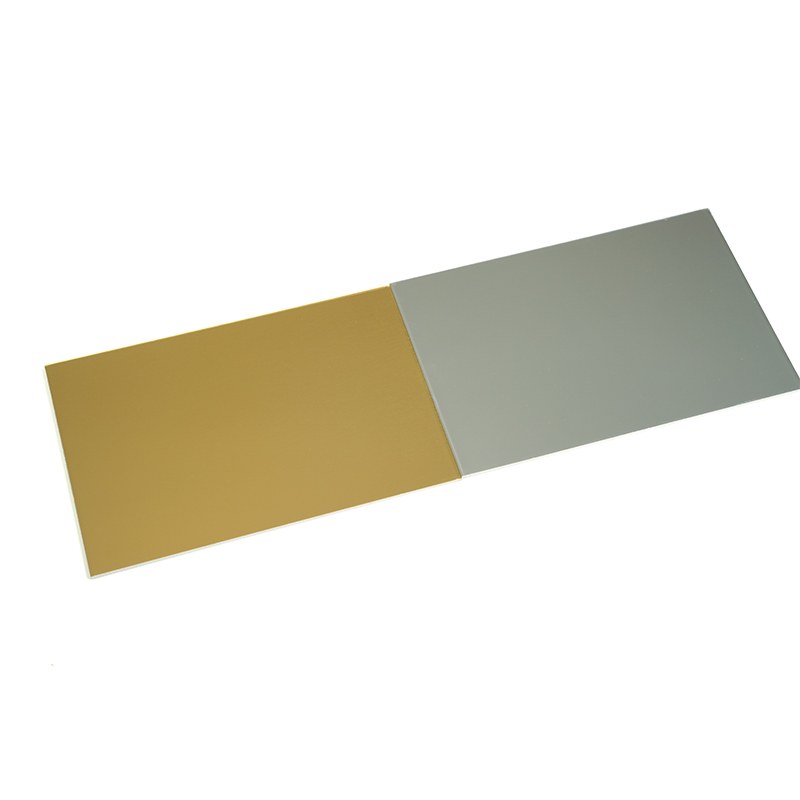

A stainless steel composite panel, also known as a stainless steel sandwich panel or stainless steel composite material, is a composite material made of two thin layers of stainless steel bonded to a core material (usually polyethylene, mineral-filled, or aluminum). This unique structure gives it a series of unique advantages:

Lightweight: This is one of the biggest advantages of stainless steel composite panels. Because the core material has a much lower density than stainless steel, the weight of a stainless steel composite panel can be significantly less than a solid stainless steel sheet of the same thickness. This greatly reduces the load on building structures and makes it easier to transport and install.

Excellent Rigidity and Flatness: Despite being lightweight, the sandwich structure gives the stainless steel composite panel extremely high rigidity. It maintains excellent flatness and is not easily deformed, making it particularly suitable for large-scale curtain walls and decorative panels.

Cost-Effective: By reducing the amount of stainless steel used while still maintaining its aesthetic and corrosion-resistant properties, stainless steel composite panels effectively lower material costs.

Fabrication Flexibility: Stainless steel composite panels can be grooved, bent, and fabricated much like traditional aluminum composite panels, allowing for a variety of complex shapes and providing designers with a wider range of creative possibilities.

Of course, stainless steel composite panels have their limitations. Due to the nature of the core material, their fire resistance and overall strength can vary, and they are generally not as strong as solid stainless steel. Additionally, if the surface stainless steel layer is damaged, the core material may be exposed, which can affect the overall aesthetics and durability.

The choice of material depends on your specific application needs. Here are some simple points to consider:

If your project has extremely high demands for structural strength and corrosion resistance, for example, in marine environments, heavy industrial equipment, or applications that require high impact resistance, solid stainless steel is the safer and more reliable choice.

If your project prioritizes lightweight design, flatness, and cost-effectiveness, such as in architectural curtain walls, interior decoration, elevator interiors, or vehicle panels, a stainless steel composite panel would be a more cost-effective and design-flexible solution.

In summary, solid stainless steel represents the strength and reliability of traditional craftsmanship, while stainless steel composite panels represent the innovation of modern material science in lightweight design and functionality. Understanding their differences will allow you to make the most suitable choice for your project, balancing performance, aesthetics, and cost.