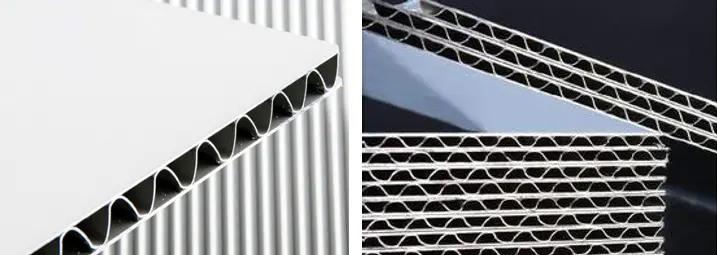

Aluminum corrugated panels are a ubiquitous sight in various industries, and for good reason. Their unique design, characterized by a series of parallel folds or ridges, grants them exceptional strength-to-weight ratios and versatility. This inherent strength, coupled with aluminum's natural properties, makes these panels ideal for a wide range of applications, from architectural facades to industrial enclosures.

At their core, the purpose of aluminum corrugated panels revolves around protection, structural integrity, and thermal management.

One of the primary functions of these panels is to provide robust protection against environmental factors. Aluminum's inherent resistance to corrosion, rust, and UV degradation makes corrugated panels a superior choice for outdoor applications compared to many other materials. They effectively shield underlying structures from rain, snow, wind, and harsh sunlight, contributing to the longevity and reduced maintenance needs of buildings and equipment. This protective quality is particularly valuable in industrial settings where sensitive machinery or components require a reliable barrier. For instance, they can act as an effective thermosheath or thermal protection tube, safeguarding delicate instruments from extreme temperatures or mechanical impact.

The corrugated profile significantly enhances the panel's rigidity and load-bearing capacity without adding substantial weight. This makes them an excellent material for structural applications. They are commonly used as roofing and siding material for industrial buildings, warehouses, and agricultural structures. The corrugations create a larger surface area, allowing for better distribution of stress and increased resistance to bending and buckling. This structural prowess also makes them suitable for non-load-bearing applications where rigidity is still desired, such as partitioning, fencing, and even decorative elements.

Beyond physical protection, aluminum corrugated panels play a crucial role in thermal management. Aluminum is an excellent reflector of radiant heat, which can significantly contribute to energy efficiency. When used as exterior cladding, these panels can reflect a substantial portion of solar radiation, reducing heat gain within a building during warmer months. Conversely, their ability to trap air within the corrugations can provide a degree of insulation, helping to retain heat in colder climates. This dual function in thermal regulation makes them a valuable component in achieving sustainable building practices. In applications requiring precise temperature control, such as around a high-temperature heat shield, furnace tube, or pyrometer sheath, the reflective and insulating properties of aluminum corrugated panels can be critical for operational efficiency and safety.

While protection and structural integrity are paramount, the aesthetic appeal and economic benefits of aluminum corrugated panels cannot be overlooked. They offer a clean, modern, and often industrial aesthetic that is favored in contemporary architecture. Furthermore, aluminum is a highly recyclable material, contributing to a project's environmental sustainability. Their lightweight nature also simplifies transportation and installation, leading to reduced labor costs and faster project completion times.

In conclusion, aluminum corrugated panels serve a multifaceted purpose, acting as a durable and versatile material that offers protection, structural support, and thermal management. Their broad application across various industries underscores their effectiveness and value, solidifying their position as a fundamental component in modern construction and industrial design.