The construction industry is continuously evolving, and one of the key innovations leading the charge is the aluminum core composite panel. Also referred to as metal core composite boards or aluminum cladding panels, these advanced materials offer a mix of durability, sustainability, and modern aesthetics, making them a game-changer in both industrial and architectural applications.

Understanding Aluminum Composite Panels with Core Technology

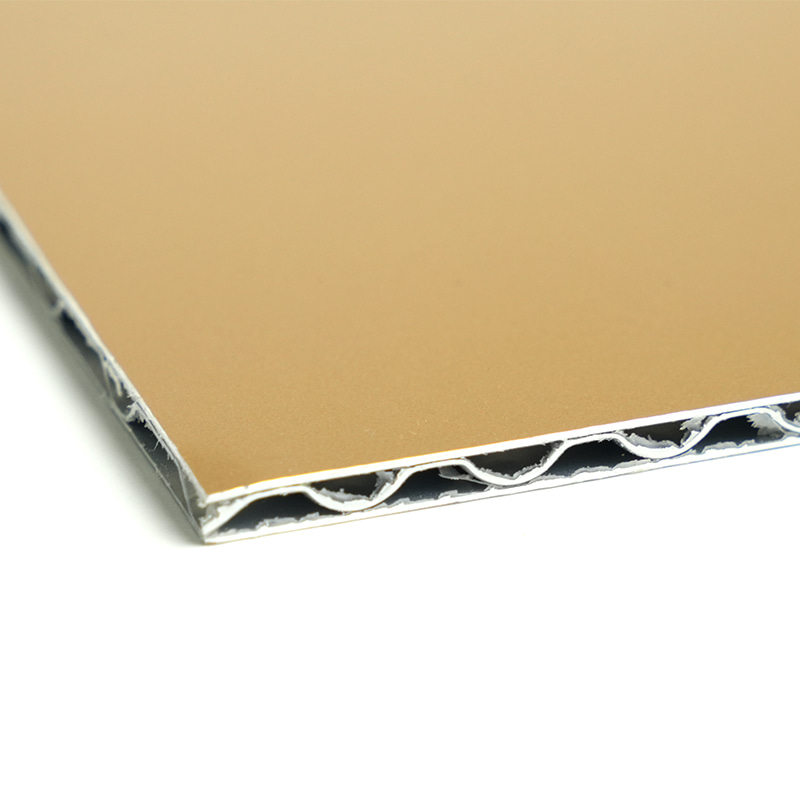

Aluminum core composite panels (ACCPs) are engineered products made by sandwiching an aluminum core—usually honeycomb or corrugated—between two outer aluminum skins. This unique composition results in a panel that is not only lightweight but also incredibly rigid and strong.

These materials differ from traditional aluminum composite panels (ACP) that use a polyethylene or mineral core, offering improved fire safety, stability, and load-bearing capacity.

Structural and Functional Superiority

One of the major advantages of aluminum core panels is their dimensional stability. They do not warp, crack, or expand significantly under extreme temperature fluctuations. Additionally, the high impact resistance and vibration damping properties make them suitable for a wide range of applications, from building exteriors to railway carriage interiors.

Because of their lightweight nature, installation becomes much easier and cost-effective, especially in high-altitude construction or structures requiring significant panel coverage.

Design Possibilities and Aesthetic Flexibility

Designers and architects love aluminum composite panels with core reinforcement for the creative freedom they offer. These panels can be customized in various sizes, finishes, and colors, providing a seamless blend of form and function.

From aluminum facade panels with glossy finishes to woodgrain aluminum sheets for natural aesthetics, the adaptability of these products is unmatched. They can be laser-cut, bent, or shaped without compromising structural integrity, allowing for innovative design elements.

Durability That Lasts

These aluminum cladding boards are resistant to weathering, corrosion, and chemical exposure. Their ability to withstand harsh environmental conditions makes them suitable for industrial complexes, airports, commercial towers, and even marine environments.

Maintenance is minimal; simple periodic cleaning keeps them looking new for years. Unlike traditional materials, aluminum core panels do not require painting or refinishing, further reducing long-term costs.

Eco-Friendly and Cost-Efficient

As sustainability becomes more important in construction, aluminum core composite panels stand out. Being 100% recyclable, they contribute to green building certifications like LEED and BREEAM. The production process also consumes less energy compared to alternative metal-based panels.

Additionally, the combination of long lifespan, low maintenance, and ease of installation translates into lower lifecycle costs, offering substantial savings over time.